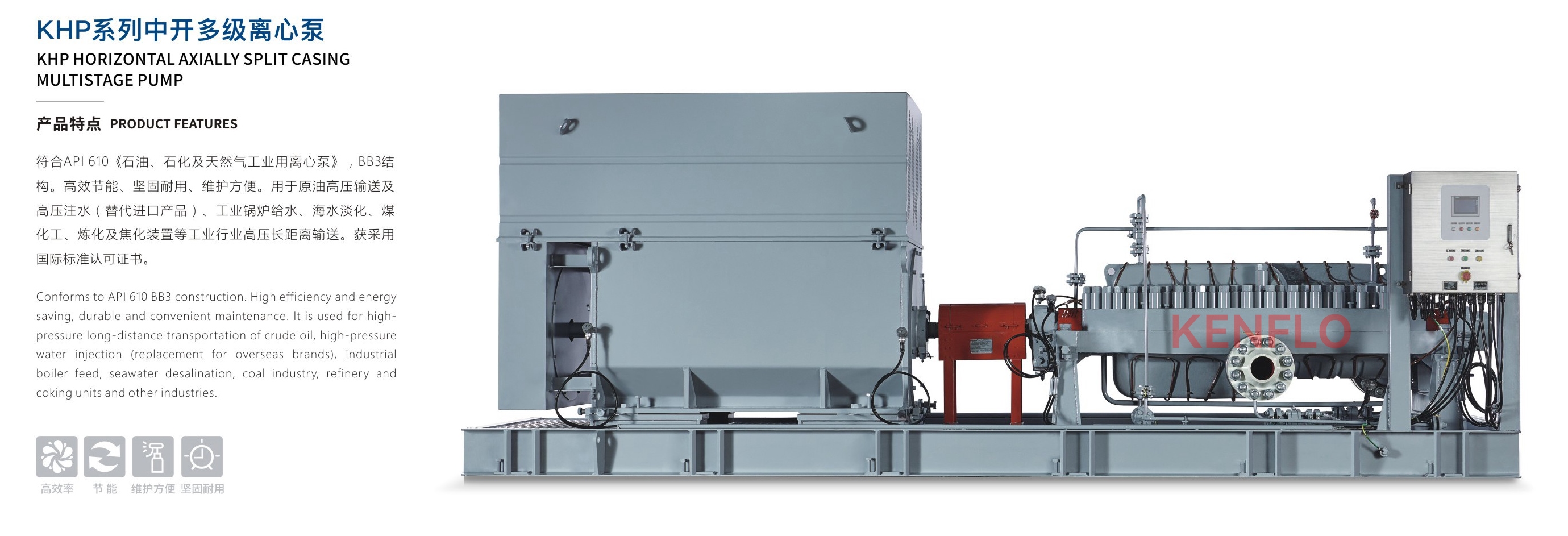

KHP type horizontal split split multistage pump

Product Overview

KHP pump is the latest horizontal split split multistage pump developed by our company. It is a new generation of high-pressure multistage pump products developed on the basis of selecting excellent hydraulic models and using CFD fluid dynamics calculation methods and computer-aided design methods, which has the advantages of high efficiency and energy saving, sturdy and durable, and convenient maintenance.

Fields of application

KHP series pumps can be used for long-distance transportation of crude oil (or refined oil), high-pressure water injection in oilfields, seawater desalination, transportation of chemical raw materials (poor methanol, etc.), transportation of coal chemical ash water, transportation of coal chemical condensate, transportation of solvent, steel descaling, hydraulic coal mining, boiler feed water and other industries that require high pressure.

Features:

Axial division of the pump casing - the suction inlet and discharge outlet are all below the pump axis, perpendicular to the axis, and easy to install and maintain;

Twin vortex chamber design - can balance the hydraulic radial force, prolong the service life of bearings and mechanical seals;

High efficiency - excellent hydraulic model and compact flow channel design;

Symmetrical arrangement of impellers - long-term balance of axial forces;

High balance requirements - the impeller is tested for static balance, and the rotor components are tested for high dynamic balance:

Good anti-cavitation performance - the first stage impeller adopts a double-suction impeller or an impeller with good cavitation performance;

Reliable bearings - the pump bearings are combined with imported brand bearings, which can better balance the force of the rotor:

Near-centerline installation – can convey liquids with higher temperatures;

Heavy-duty bolts - can effectively prevent the deformation of the pump casing and interstage leakage;

Convenient monitoring - the bearing body is equipped with vibration and temperature measurement device monitoring interface, which can be monitored online:

High configuration - reasonable material matching + all stainless steel rotor parts, with cartridge mechanical seals;

Fully compliant with API 610 BB3 pumps;

Product standards

GB/T 3215-2007(Equivalent to adoptionAPI610: 2004)

Performance Range (Spectra):

Sectional view: