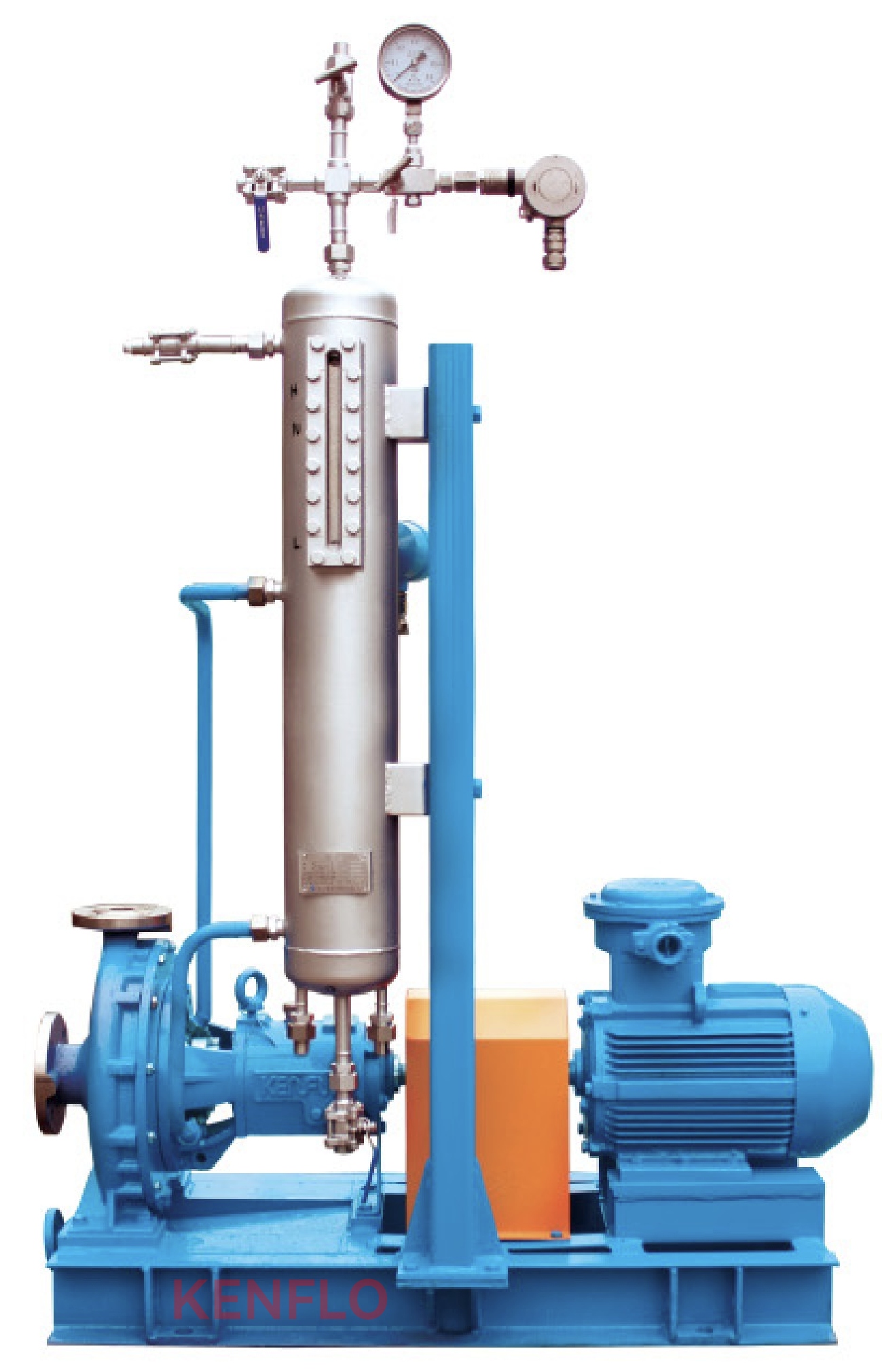

KCC series standard chemical pump

1、Product Overview

KCC series standard chemical pump is a new generation of high-quality products developed by KENFLO (Guangdong Kenflo Pump Industry Co., Ltd., hereinafter referred to as KENFLO) using CFD technology (computational fluid dynamics). Its superior hydraulic performance and excellent structural characteristics ensure the reliable and low-cost operation of the product.

2、Scope of application

Chemical and petrochemical industry, oil refineries, paper industry, sugar industry, sewage treatment, food and medicine industries.

3、Conveying medium:

Sewage, seawater, oil, solvents, acidic aqueous solutions, hydroxides, amines (amino), some acids, etc.

Medium temperature:

-40°C~+175°C(Depends on the characteristics of the medium and the sealing material)。

4、Main parameters:

Pump Caliber: Suction40~300mm

discharge 25~250mm;

Rotate speed:1450r/min、1480r/min和2900r/min;

Flow rate:3~1500m3/h;

Head:5~160m;

Housing pressure:1.6MPa(20°C时);

Hydrostatic test pressure: max2.4MPa。(Inlet pressure = shell pressure - shut-off head)

5、Key features:

◆ Patent - The combination of the conical fit and the radial shaft seal protected by the patent not only effectively improves the strength of the tie shaft but also prevents the erosion of the conveying medium (patent number: ZL 02272936.4)

◆ Impeller/Housing - Optimized design, increased flow rate design and 500mm nominal impeller diameter design, so that the energy range of the series exceeds the S02858 standard, and has a wider range of performance coverage and better performance indicators than IH pumps.

◆ Shaft Seal Jacket – The shaft seal cooling/heating jacket can be set on the pump cover to effectively improve the working condition and service life of the mechanical seal, while reducing the impact of heat transfer on the bearing life.

◆ Bearing - Bearing combination structure in accordance with API610. The impeller end is a cylindrical roller bearing and the drive end is a back-to-back angular contact ball bearing with a load carrying capacity that exceeds that of the pump.

◆ Shaft Seals – Single, double, cartridge and packing seals are available.

◆ Split packing gland - The packing gland of the dovetail split structure not only ensures the reliability of the binding positioning, but also provides space for changing the packing.

◆ Axial force balance - the axial force is balanced by the combination of sealing ring + balance hole and back-to-back angular contact ball bearing.

◆ Transmission - the use of high-performance metal elastic element flexible coupling - integral diaphragm with intermediate shaft diaphragm coupling, large bearing capacity, long service life, convenient rotor assembly and maintenance.

◆ Flange - Conventional flange connection size in accordance with the provisions of HG/T20592GB/T9113 PN16MPa, special goods can provide American standard flange in accordance with HG/T 20615 PN 2.0 MPa.

◆ Interchangeability - It can be interchangeable with a centrifugal pump that meets the GB/T5662 (ISO2858) standard.

◆ Steering – The pump rotates in a clockwise direction from the drive end.

6、material:

The material combination refers to the provisions of the tenth edition of API 610 (316 and 304 are the preferred materials, and the rest are optional material combinations).