A natural gas power plant of Shenzhen energy group used Kenflo 2bw9 roots water ring vacuum pump unit for energy saving transformation

A power plant of Shenzhen Energy Group Co., Ltd. is located on the Northeast Bank of Dapeng Bay, Shenzhen, Guangdong Province, with a current installed capacity of 3 × 390MW gas steam combined cycle unit.

The circulating cooling water of the power plant is seawater, which is taken from Dapeng Bay, about 1km northwest of the plant.

Two water ring mechanical vacuum pumps are used in the original condenser vacuum pumping device, and the matching motor power is 110KW. In this technical transformation, a 2bw9 roots water ring vacuum pump unit manufactured by Kenflo is added. The total power of supporting motors is 27kw, and the tag number is pump C. Under the condition of maintaining the vacuum of the condenser, only the newly added C pump (2bw9 roots water ring vacuum pump unit) can be operated to maintain the vacuum of the condenser. The original two high-power water ring mechanical vacuum pumps can be stopped.

The principle of 2bw9 roots water ring vacuum pump unit is as follows: Roots pump and water ring vacuum pump are both positive displacement vacuum pumps, but when the water ring vacuum pump works, it needs to use water as the working stop. When the vacuum is high, the water itself will vaporize, and the vaporized water vapor will occupy a large amount of volume, resulting in a significant reduction in the pumping rate of the water ring vacuum pump under high vacuum conditions; And roots vacuum pump, at 1kPa Under the working conditions above a (absolute pressure), the pumping rate is basically constant, because there is no water vapor vaporized in the roots pump to occupy the volume. However, the high-efficiency working range of Roots vacuum pump is only limited to a certain compression ratio. Therefore, in order to work efficiently, the outlet of roots pump must be pumped by water ring vacuum pump, which is also called the front pump of roots pump. Such units are widely used in the chemical industry and pharmaceutical industry. Now it has been applied in many thermal power plants, and the energy-saving effect is obvious. After adding 2bw9 roots water ring vacuum pump unit, the thermal power plant can achieve 60% ~ 70% energy saving effect.

The implementer of this project is Huizhou kenfulai Pump Sales Co., Ltd. the 2bw9 roots water ring vacuum pump unit is produced by Guangdong kenfulai Pump Industry Co., Ltd. the on-site operation control cabinet is designed and supervised by Huizhou kenfulai Pump Sales Co., Ltd. and is connected with the user's DCS control system to realize remote / automatic control of DCS. The on-site installation and commissioning of the equipment were also completed by the construction personnel of Huizhou kenfulai Pump Sales Co., Ltd.

This natural gas power plant is located on the seashore of a peninsula, with a beautiful environment. Entering the factory Avenue, the beautiful factory buildings and the blue sky and white clouds set off each other.

The white chimney means that this is an environmentally friendly natural gas power plant. Compared with traditional coal-fired power plants, natural gas power generation has less impact on the environment. However, now the new technology coal-fired power plants are also very environmentally friendly after adopting flue gas treatment and desulfurization and denitration environmental protection treatment.

Above: foundation bolt grouting and other works have been carried out on site for 2BW9 unit. Wait for further piping work and electrical wiring.

After the installation of the on-site electric control cabinet, conduct power on inspection. The cabinet is made of 304 stainless steel.

Above: Kenflo 2BW9 roots water ring vacuum pump unit has been installed and is waiting for startup and linkage commissioning.

The 2BW9 roots water ring vacuum pump unit has been installed and tested. All pipes and interfaces are well sealed. The commissioning and trial operation conditions are available.

The above figure is the nameplate of the unit. The model and specification are: 2BW9 103-0BD2-0Y1450. The supporting power is 11 + 15kw, that is, 27kw in total. The weight of the unit is 3.2T.

After the installation of the unit and the inspection before commissioning, the joint commissioning was conducted with the owner.

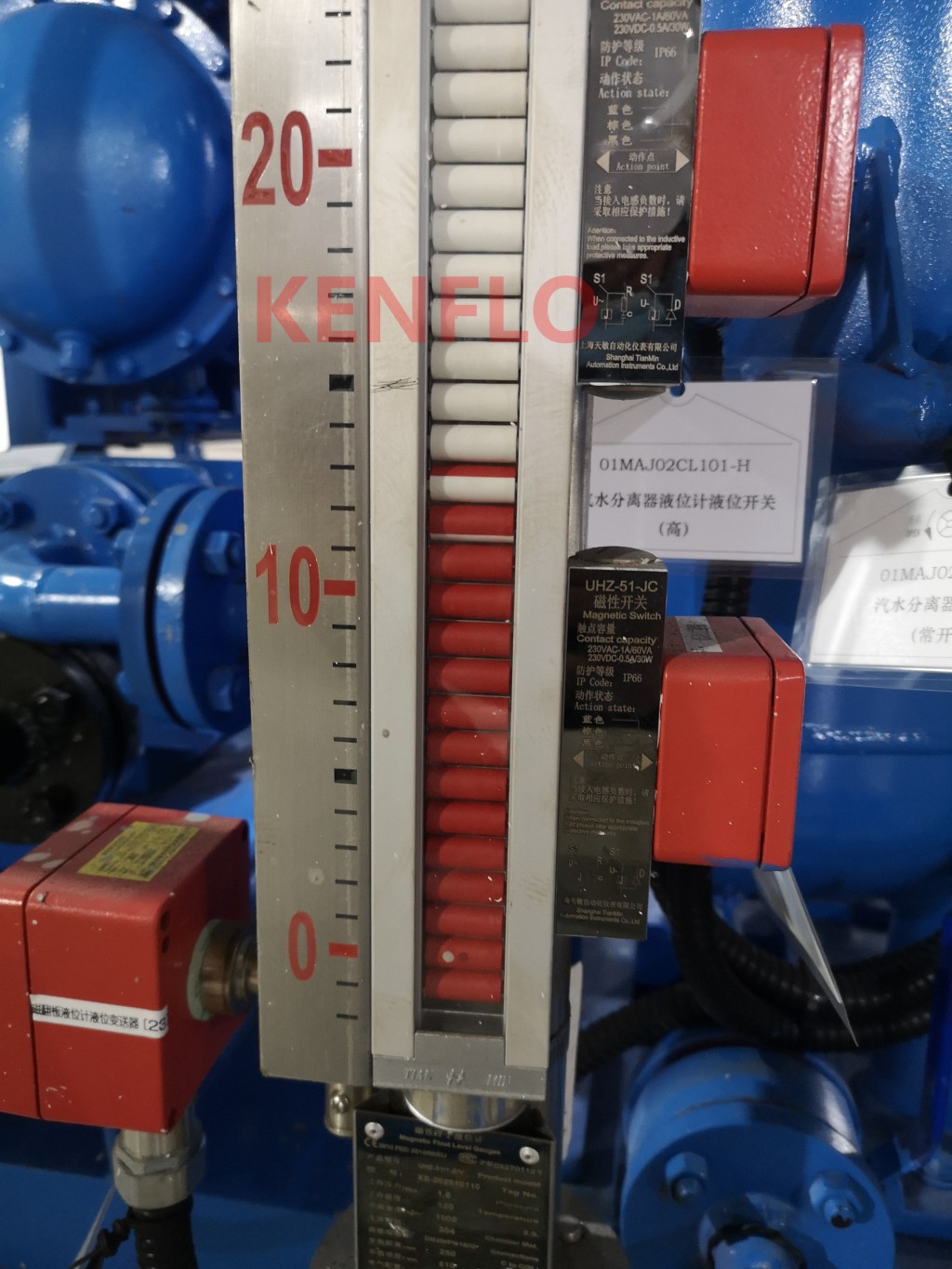

The magnetic flap liquid level meter is used, and the liquid level transmitter is matched. At the same time, the high and low liquid level switches are also matched to realize the data detection of analog quantity and the control of switching quantity. And they confirm each other.

After startup, the operating current is normal. Under DCS remote control mode, interlocking is normal.

Above: the owner's on-site personnel are checking the operation status data to check various operation parameters during unit commissioning.

After commissioning, after the unit is put into operation, the inlet pressure of 2BW9 roots water ring vacuum pump unit is 2.71kpa.A. Reached the back pressure value agreed in the contract and exceeded the customer's expectations. The transformation project has achieved good results. Project acceptance is completed.

共有 0 条评论