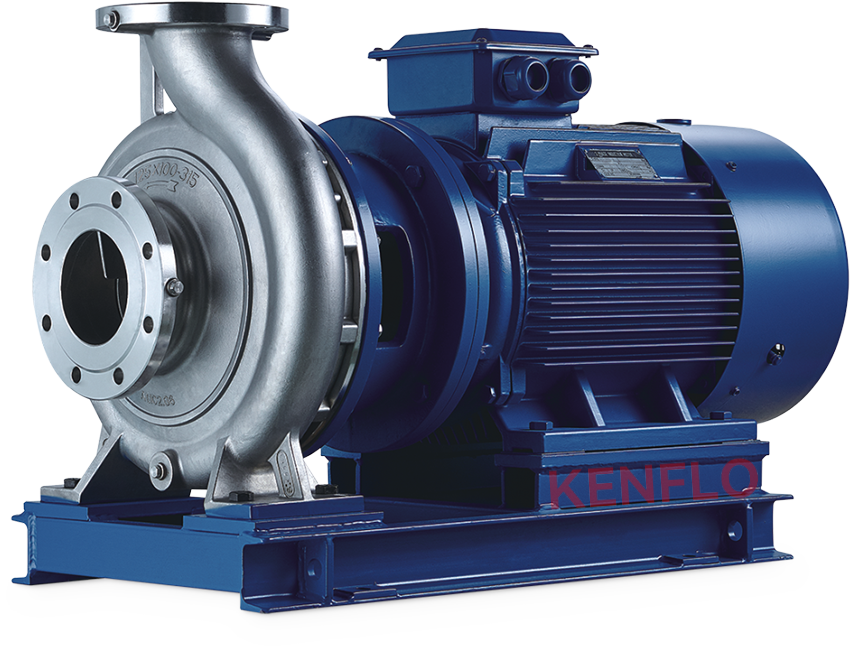

KMP series direct-coupled single-stage centrifugal pump

1. Product introduction:

KMP series centrifugal pump is a new generation of high-efficiency, low-maintenance pump products developed and designed by KENFLO using high technology. Its excellent hydraulic model and structural characteristics ensure that users can effectively reduce the operating cost of the pump in various applications. The motor of KMP series single-stage centrifugal pump adopts the design of elongated shaft, and the impeller of the pump is directly installed on the motor shaft, which is compact in structure, and also saves the work of coupling alignment, and has low requirements for installation and construction. It is an innovative centrifugal pump product with low cost and low installation requirements.

2、 product features:

1. The size of the pump body conforms to the international standard of ISO2858 (GB/T 5662) - it has the same performance and interchangeability of the pump casing connection with other products that meet the requirements of the standard, and the axial size is shorter and the floor space is less. The technical conditions meet the ISO9908 (GB/T 5657);

2. Structural design to improve quality - the pump body adopts a high-efficiency volute shape;

3. Single-end mechanical seal - suitable for occasions where leakage is not allowed;

4. Direct frame - the pump and the motor are directly connected through the direct frame, which is simple and compact in structure;

5. Impeller balance - G6.3 balance accuracy grade is adopted.

3. Technical parameters:

Head:5.2-160m

flow rate:9.5-400m3/h

Pump caliber:inhale 50~150mm,discharge32~125mm

The shell is under pressure:1.6MPa(Maximum permissible pressure at the inlet=The shell is under pressure—Shut down the head)

Medium temperature:-15℃~+104℃

4、the field of application:

It is used to pump clean water or weak corrosive liquids without solid particles and fibers. It is widely used in high-rise water supply, building fire protection, central air conditioning water circulation, circulating water supply in process systems, cooling water circulation, boiler water supply, industrial water supply and drainage, water conservancy irrigation, etc.