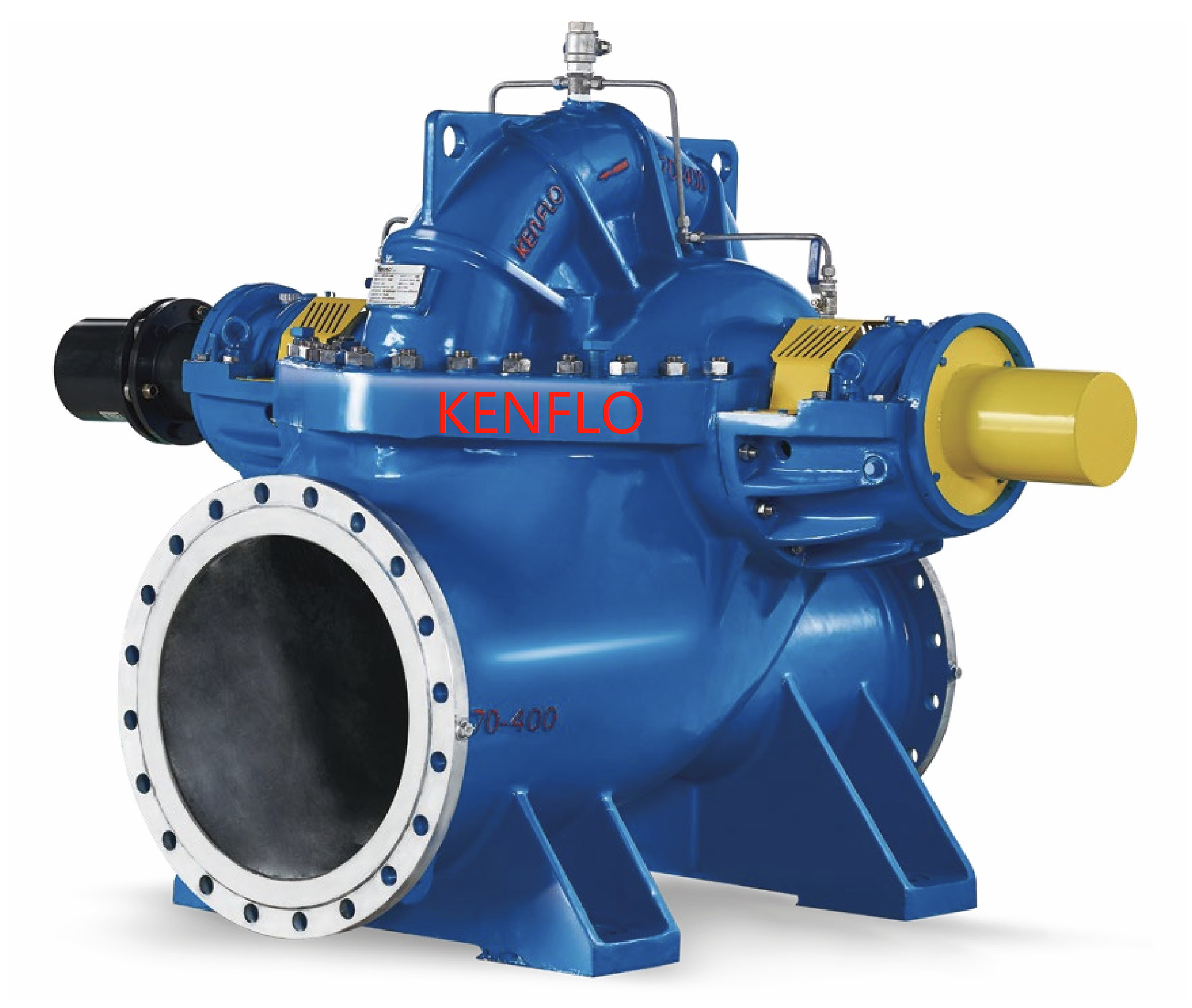

KPS single-stage, double-suction centrifugal pump

KENFLO's KPS split double suction pump is the best solution for water supply systems.

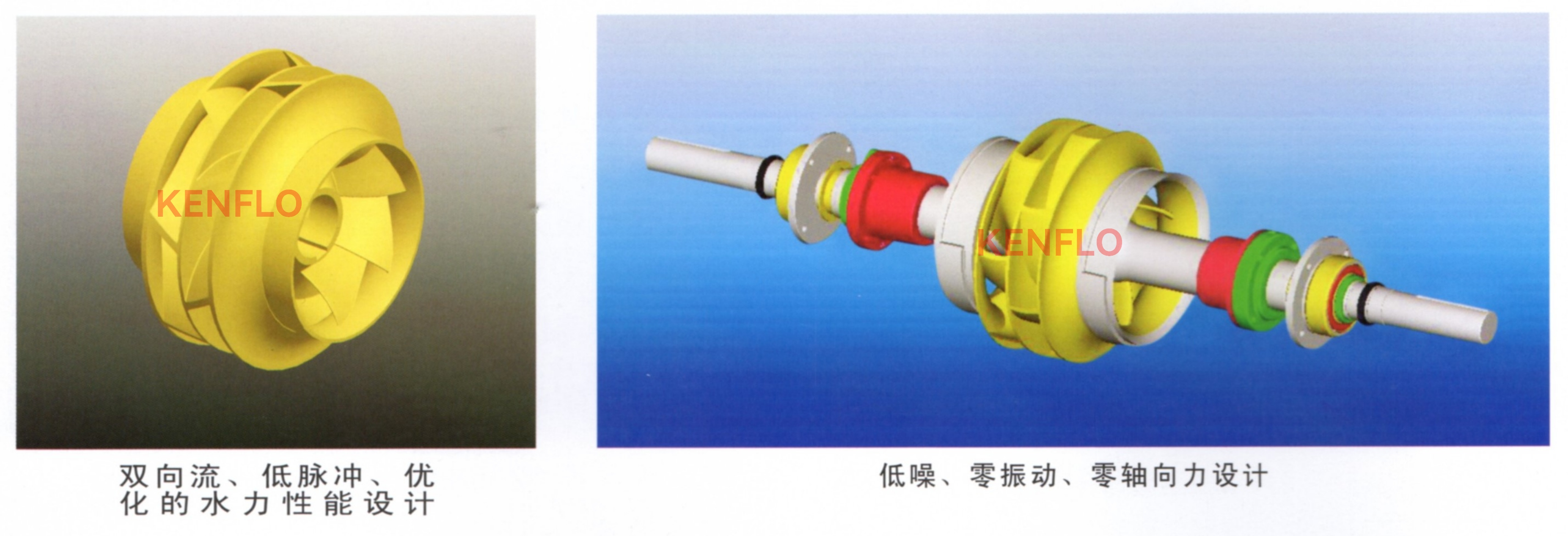

KPS pump is the latest single-stage double-suction centrifugal pump launched by our company. It uses the most advanced fluid dynamics calculation method - CFD computer-aided design method to develop a new generation of pump products, with high efficiency and energy saving, low pulse, low noise, rugged and easy maintenance and other advantages.

A wide range of performance options are available:

Technical parameters:

There are a total of 52 specifications in this series, which can provide hundreds of performance options with different impeller diameters and different speeds.

The diameter of the inlet and outlet of the pump:

Suction diameter: DN150~DN1400mm

Discharge diameter: DN100~DN1200mm

Flow rate: max. 25,000 m³/h

Head: up to 160 meters

Flange design pressure:

1.0MPa :Nominal head < 95m

1.6MPa :95m < Nominal head < 130m

2.5MPa:Nominal head > 130m

Applicable medium temperature:-15℃~+104℃

Fields of application:

KPS series single-stage double-suction centrifugal pump is generally used to pump clean water or weak corrosive liquid without solid particles and short fibers, and can be widely used in the following fields: Circulating water supply in the engineering system, industrial water supply and drainage, urban water supply, cooling water circulation, central air conditioning water circulation, high-rise water supply, building fire protection, boiler water supply, water conservancy irrigation, especially suitable for water plants, paper mills, power plants, thermal power plants, steel mills, chemical plants, irrigation area water supply. When applying dry and non-clean water occasions, special materials can be used, such as sprayed SEBF material or 1.4460K duplex stainless steel, which is especially suitable for seawater transportation.

Advantages of KPS pumps::

★ Sturdy and beautiful appearance: The high-strength pump casing design and the overall optimized design of the shape make it refreshing.

★ Stable and efficient: optimized design, symmetrical impeller, no axial force, stable operation and long life.

★ Easy installation: The pump shaft has a double shaft extension that can be driven from either end and can be determined by the user depending on the site conditions. The suction inlet and the discharge outlet are below the axis of the pump, perpendicular to the axis, and the pump body is horizontal and open, so there is no need to disassemble the inlet and outlet pipelines and motors during maintenance.

★ A variety of shaft seals to choose from: packing seals, injection soft packing seals, mechanical seals, etc. Independent Shaft Seal Box – Packing Packing, Injected Soft Packing, Single Acting Machine, Double Acting Machine Seal and other sealing forms can be interchangeable by simply replacing the shaft seal components.

★ Reliable bearings and seals: imported deep groove ball bearings and oil seals, and the bearings are lubricated with grease or oil.

★ Setting of wear-resistant and corrosion-resistant shaft protection sleeve: In the overcurrent part, the spindle is protected by the shaft sleeve. In actual operation, the spindle has no friction and is not in direct contact with the pumped medium.

★ Reliable positioning of the bearing seat: The positioning is positioned in the form of positioning pin or stop respectively, and the positioning is reliable, and the bearing seat of KPS pump adopts a split half structure, which is easy to install and maintain.

★ High-grade material matching in line with the new design concept: The conventional minimum configuration of the spindle is 20Cr13, and 1.4313 stainless steel, 1.4462 duplex stainless steel and ultra-high strength 630 stainless steel can also be used, and the bolts and other connecting parts are all made of stainless steel.