The maintenance of 200KW low-voltage inverter in a water plant in Shenzhen was completed

At a water plant in Shenzhen, the frequency converter had a blown failure. The time when the fault occurs is the time when the inverter stops output, that is, when the inverter fails, the inverter is not running, but is in the power-on standby state. The state of the fault is the bomber, that is, there is an internal insulation breakdown problem, and there is a local short circuit in the trip. User feedback, heard a loud noise similar to a cannon bamboo in the frequency conversion cabinet, and then the control panel light of the inverter went out and the inverter was in a power-off state. However, the circuit breaker of the higher-level distribution cabinet did not have short-circuit protection tripping.

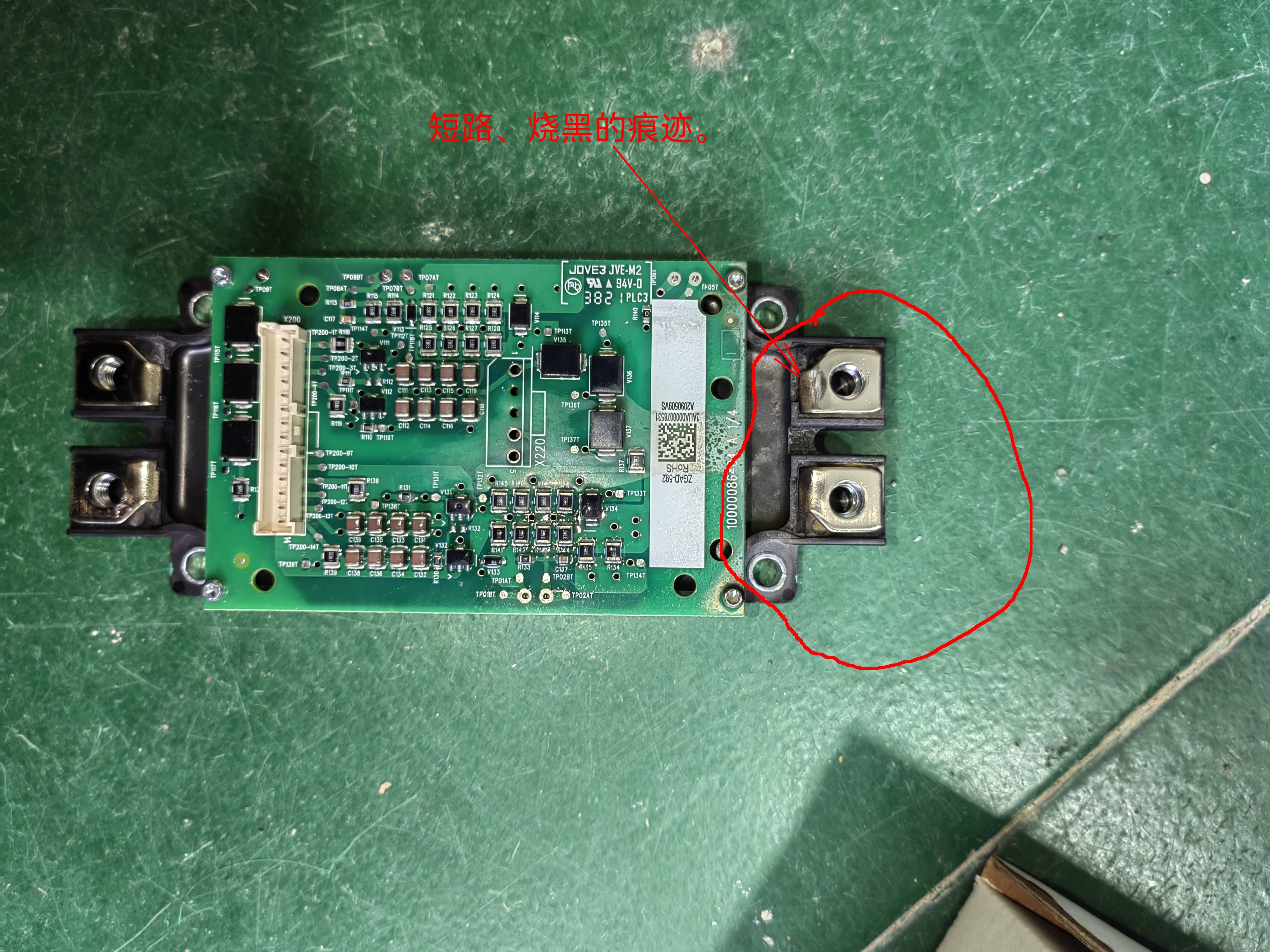

After receiving the user's notice, we went to the site on the morning of the second day to pick up the inspection. After disassembling and inspecting, it was found that the faulty components included: the AC to DC inverter was damaged, and there were traces of burnt black at the contacts; Capacitor failure failure; One phase of the quick-melt protection in the inverter cabinet has been blown out.

Preliminary judgment, mainly due to the inverter's power off storage time is too long, resulting in capacitor aging, capacitor failure after insulation breakdown, causing inverter failure and fast-melt protection fusing.

KENFLO's electrical maintenance personnel replaced the faulty components on the same day. After replacing the faulty element, it operates normally.

Above: Maintenance personnel are performing inverter repair on site.

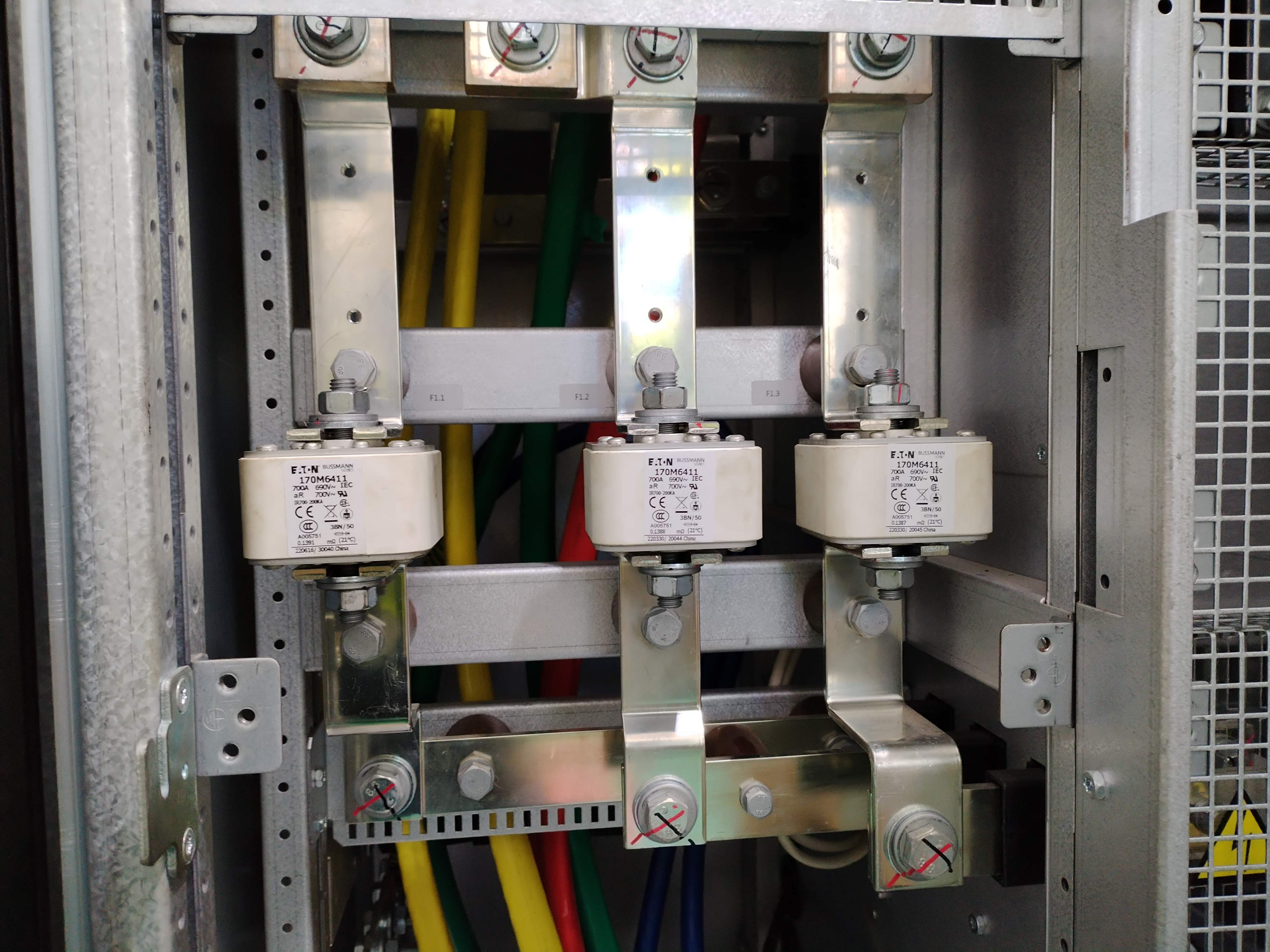

Above: Maintenance personnel replacing quick-melt protection

Above: The quick-melt protection has been replaced.

After repair, the inverter is operating normally.

共有 0 条评论