The energy-saving transformation project of the No. 8 water pump unit of Shakou Water Plant was started, and the progress of the project was rapidly advanced

Shakou Water Plant, which belongs to Foshan Water Industry Group, is an important water plant in Chancheng District, Foshan City. Chancheng District Shakou Water Plant, located in Xuefu Road, Zhangcha Street, Chancheng District, covers an area of 13 hectares and is a "garden-style" water plant. The water supply scale of Shakou Water Plant is 500,000 cubic meters per day, mainly supplying tap water in the west and north of Chancheng District, accounting for about 60% of the water consumption in the central urban area of Chancheng, serving an area of about 160 square kilometers and serving a population of about 1.2 million. The Shakou Water Plant was completed and put into operation in 1993, expanded in 1994 and 2002, and won the China Municipal Engineering Golden Cup Award in 1996. The water source of Shakou Water Plant is Dongping River, a tributary of the Beijiang River, and the conventional treatment process of "coagulation-sedimentation-filtration-disinfection" is adopted to realize real-time monitoring of the whole process online with a high degree of automation.

The No. 8 pump technology transformation project of Shakou Water Plant was carried out by general contracting. The new pump unit adopts the KPS series energy-saving horizontal split double suction pump of Guangdong Kenfulai Pump Industry Co., Ltd., the pump has high efficiency and reasonable structure, the pump supporting motor adopts a new permanent magnet synchronous motor, and the starting and adjustment adopts a high-voltage frequency converter to start, and automatically adjusts the frequency according to the outlet pressure. All equipment supply and equipment on-site installation and construction are completed by Huizhou Kenfulai Pump Sales Co., Ltd., a subsidiary of Kenfulai Pump.

According to the contract and the user's production and project schedule, the project officially started on May 16, 2023.

On-site construction tools are neatly arranged. When there is no construction in normal times, the area where the construction tools are placed is fenced.

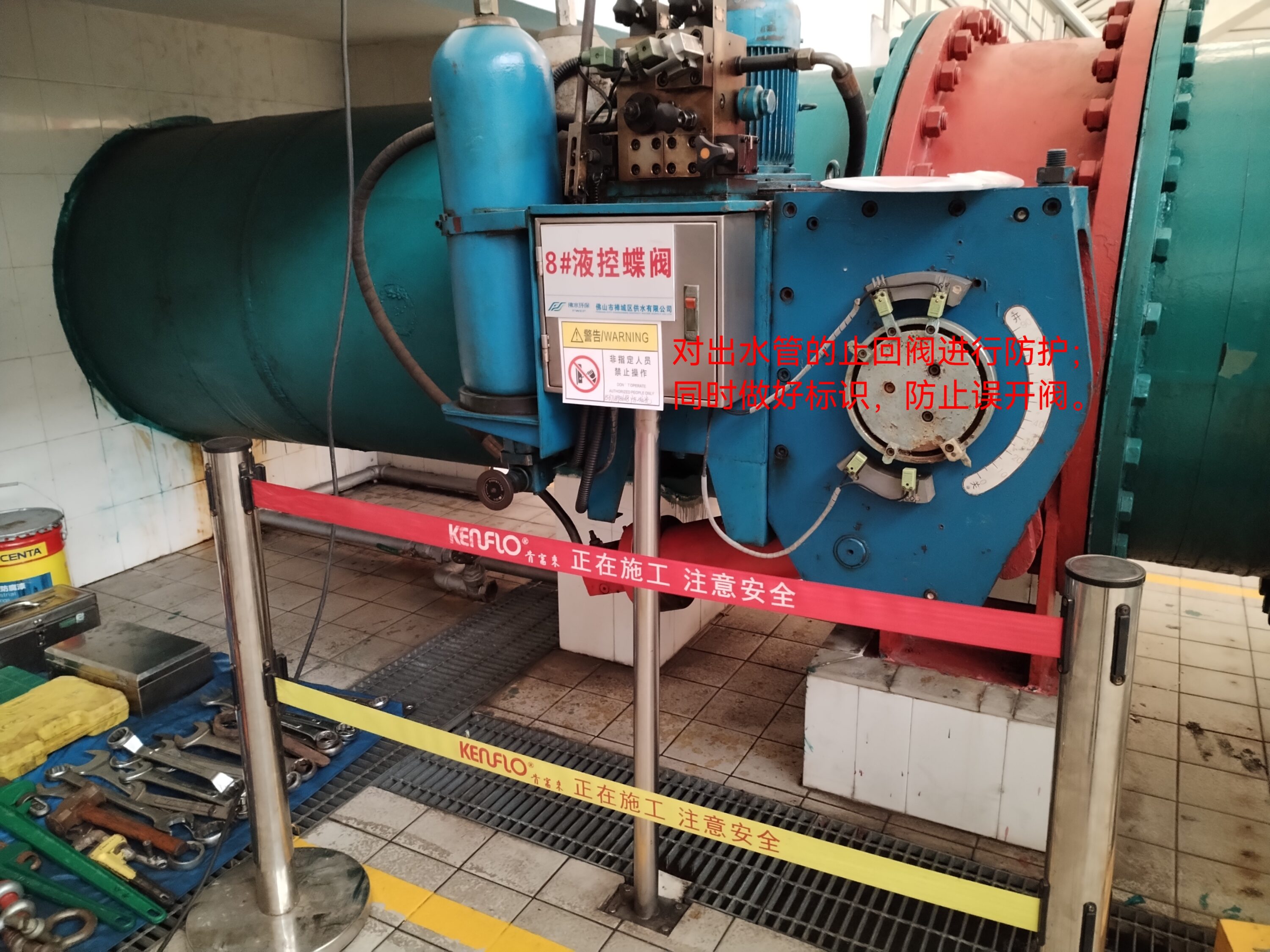

Before starting construction, the water and power cut-off operations were carried out and warning signs were hung. Multiple protection and tips to prevent accidental power-on of the equipment caused by user personnel misoperation.

The hydraulic control check valve on the outlet pipe of the old pump is also closed and powered off, and at the same time, the pressure in the hydraulic cylinder is reduced, so that the check valve cannot be opened in any misoperation. Prevent accidents such as accidental opening of valves and backflow of outlet pipes after the dismantling of the pump unit.

At the same time, the manual maintenance valve on the outlet pipe is also closed, and a warning sign prohibiting operation is hung to prevent misoperation and ensure construction safety.

After the inlet and outlet valves of the old pump are closed, the venting operation is carried out first, and according to the leakage after venting, it is judged that the valve has good sealing and small water leakage to meet the needs of engineering construction.

After high-voltage power inspection to ensure safety, the power cable of the motor was removed, and the insulation was wrapped and sealed to prevent the cable from being wet and wet.

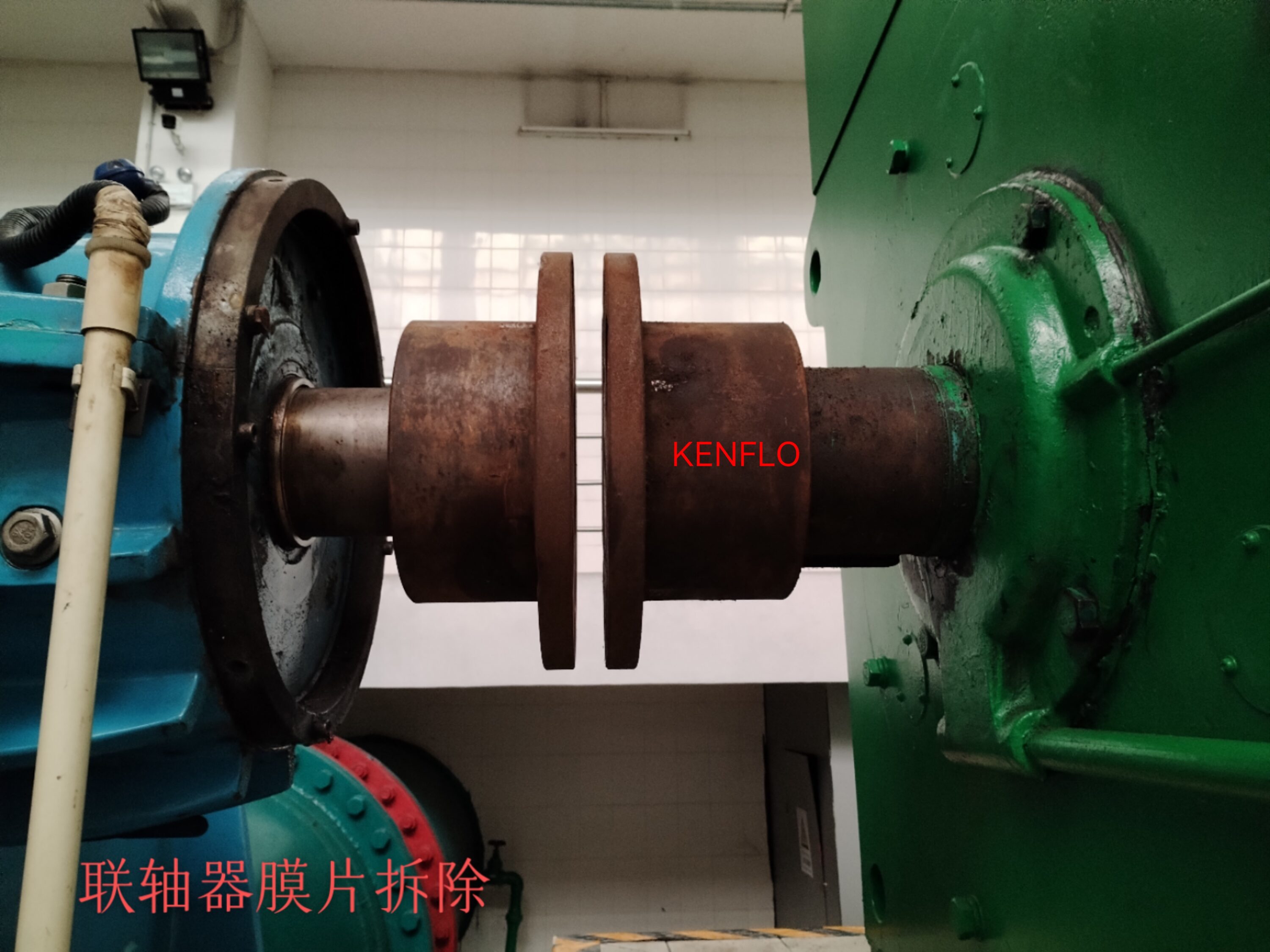

Remove the coupling guard of the old pump and remove the connecting bolts and diaphragms of the coupling.

After the coupling diaphragm is removed, the pump and motor are decoupled and the next step of the removal work can be carried out.

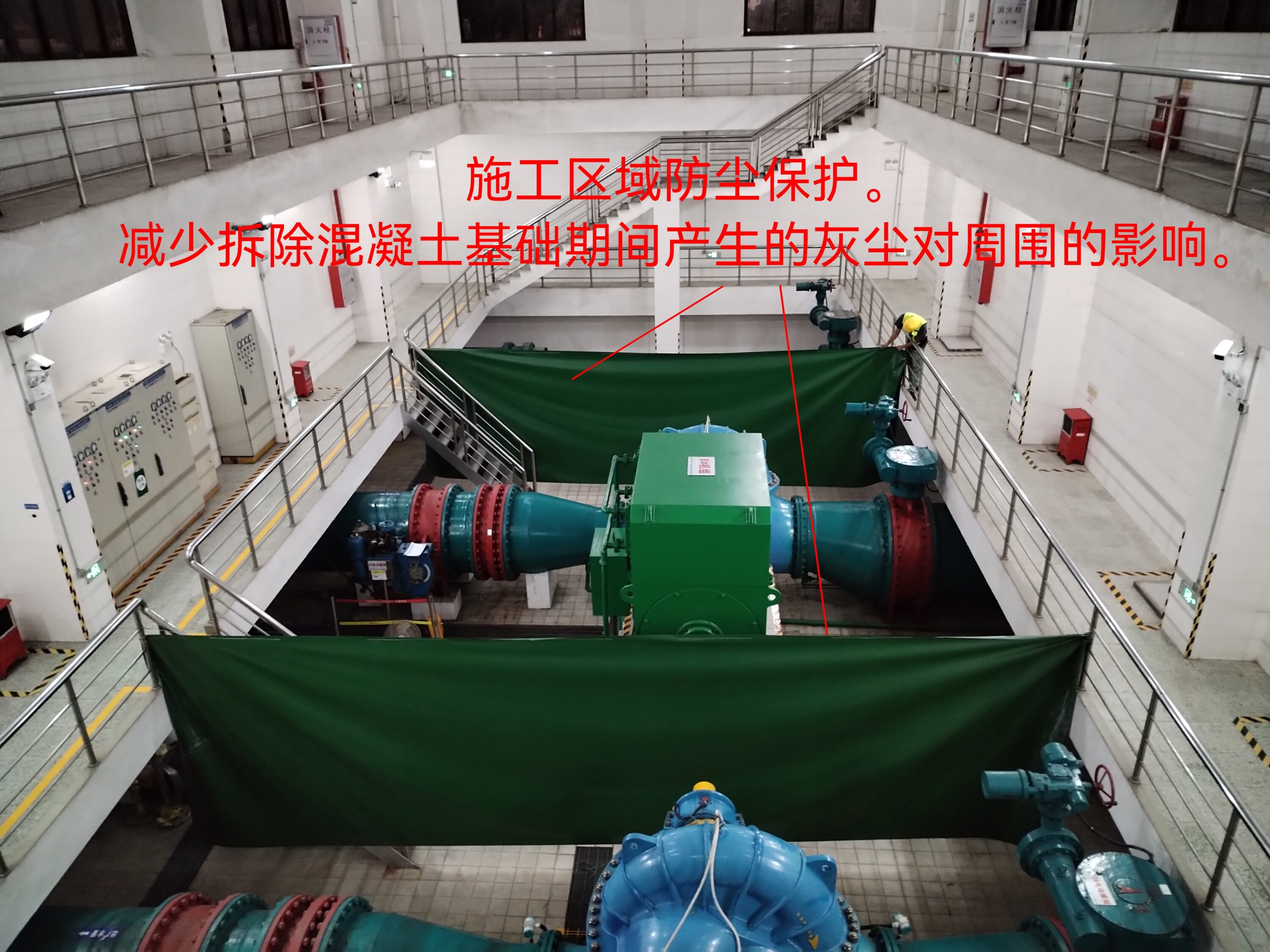

The access platform of the pump room was ground protected. The project required the demolition of the old concrete foundation, the use of dump carts for transfer, and the pouring of concrete foundations. In order to prevent damage to the ground caused by demolition work and concrete pouring work, the project deliberately used a ground protective film to protect the pump room maintenance platform.

Considering that this project needs to demolish the old concrete foundation, more dust will be generated during the demolition process. Therefore, this project has specially prepared a dust-proof fence to minimize the impact of dust on the surrounding equipment during the construction process.

After removing the anchor bolts and cooling water pipes of the motor, lift and transfer the motor. Two straps with a load capacity of 10 tons are used for lifting, and hooks with a load capacity of 10 tons are used to ensure the safety of the lifting process.

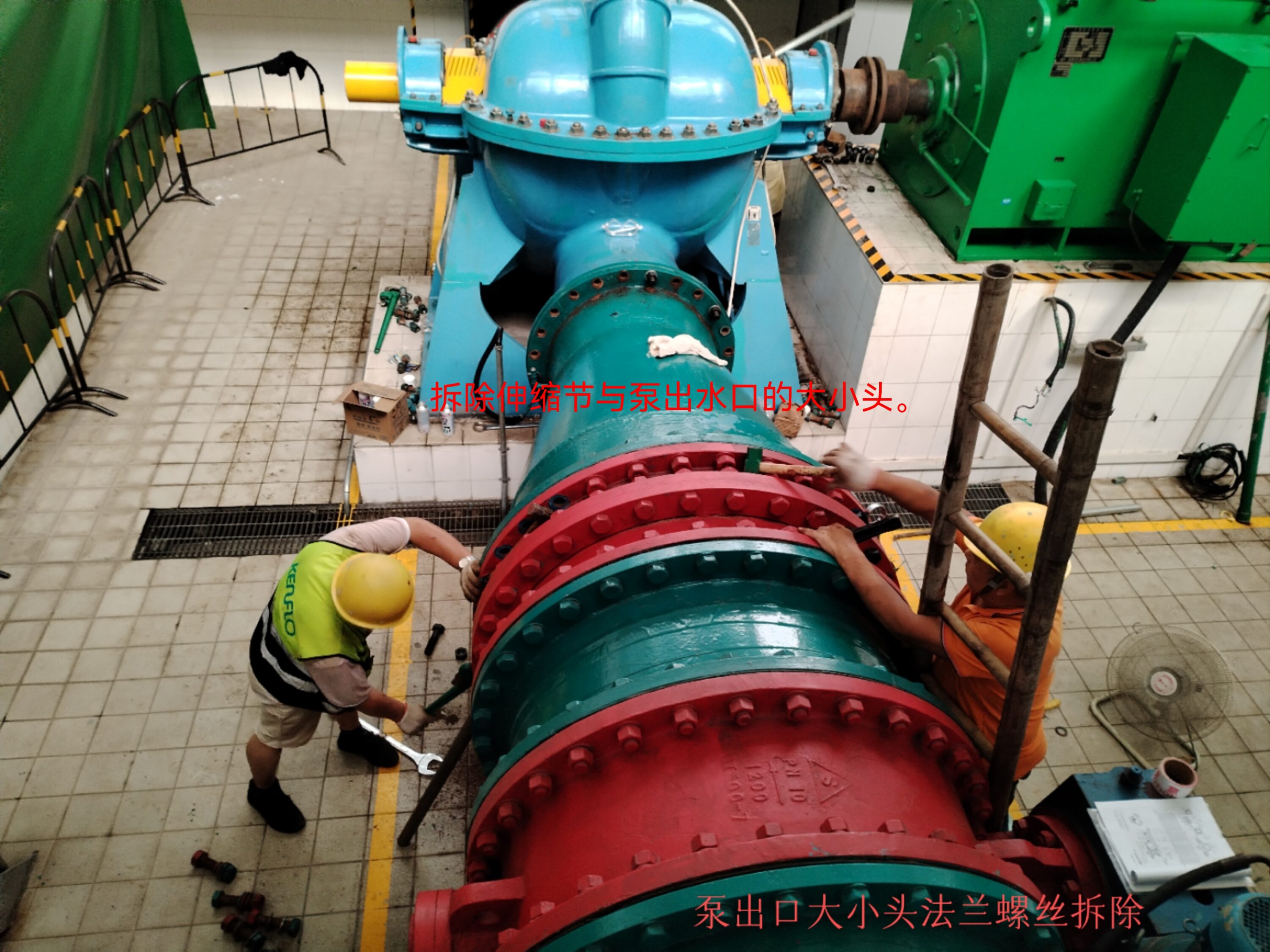

The large and small heads of the pump inlet and outlet were removed; At the same time, the expansion joints were also removed. The old expansion joint on site is a non-transmission limit expansion joint, which cannot withstand axial force, and if it is not removed, the expansion joint may fall off axially. Kenflas pump construction personnel have rich on-site experience and safety protection experience, and can identify risks and proactively prevent risk incidents.

The old pump was dismantled and lifted and transferred elsewhere. The lifting process is strictly in accordance with the lifting operation procedures, using qualified lifting tools, and first carry out test lifting to ensure safety before lifting and lifting.

After the pump was removed, the inlet and outlet pipes on site were blocked with blind plates to further prevent accidental leakage.

Demolition work was carried out on the old concrete foundation.

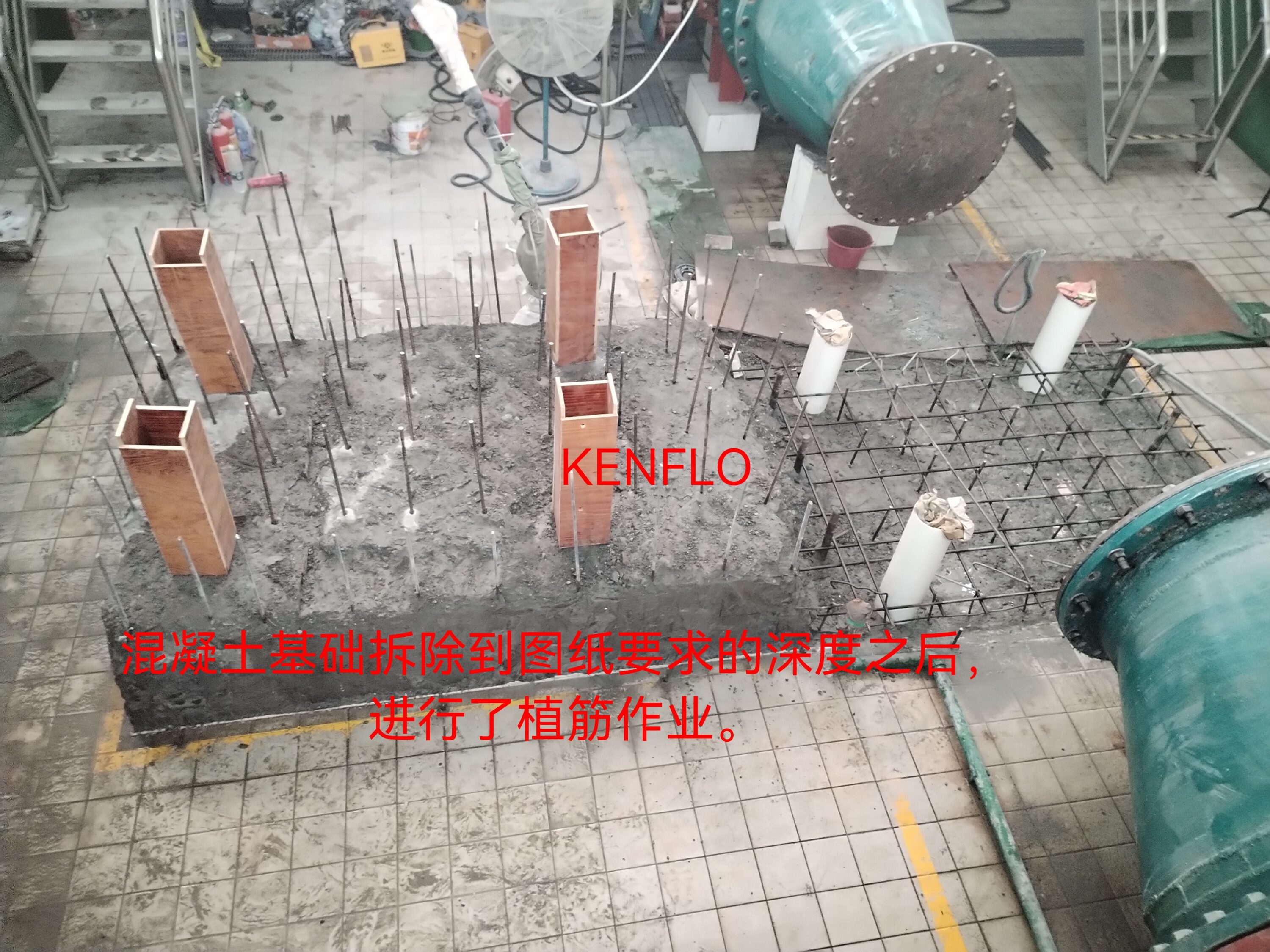

After several days of hard work, the demolition of the concrete foundation was completed. The following reinforcement operation was carried out, and the secondary grouting holes were reserved for the pump end and the motor end.

The planting bar of the concrete foundation adopts 16mm rebar, and the connection and fixing between the steel bars adopts welding method.

共有 0 条评论