The supernatant recovery device and cloud control system of the Internet of Things in the recovery pool of a waterworks

Large industrial and mining enterprises and municipal water plants are equipped with supporting surface water treatment systems. Generally, the coagulation clarification process is used to separate the surface water from solid and liquid. During this process, the clarification system will discharge muddy water with a solid content of about 2-3%. After secondary sedimentation of muddy water in the sludge sedimentation tank, the supernatant is recycled to the coagulation clarification system for recycling. At present, large industrial and mining enterprises and municipal waterworks generally install fixed self-priming pumps or fixed submersible sewage pumps on the sludge sedimentation tank to recover the supernatant in the tank. However, because the height of the suction port of the fixed self-priming pump or the installation height of the submersible sewage pump is fixed, when the sludge level in the sludge sedimentation tank is high, part of the bottom sludge is also recovered to the coagulation clarification system with water, resulting in an increase in the system's processing load and the effluent turbidity.

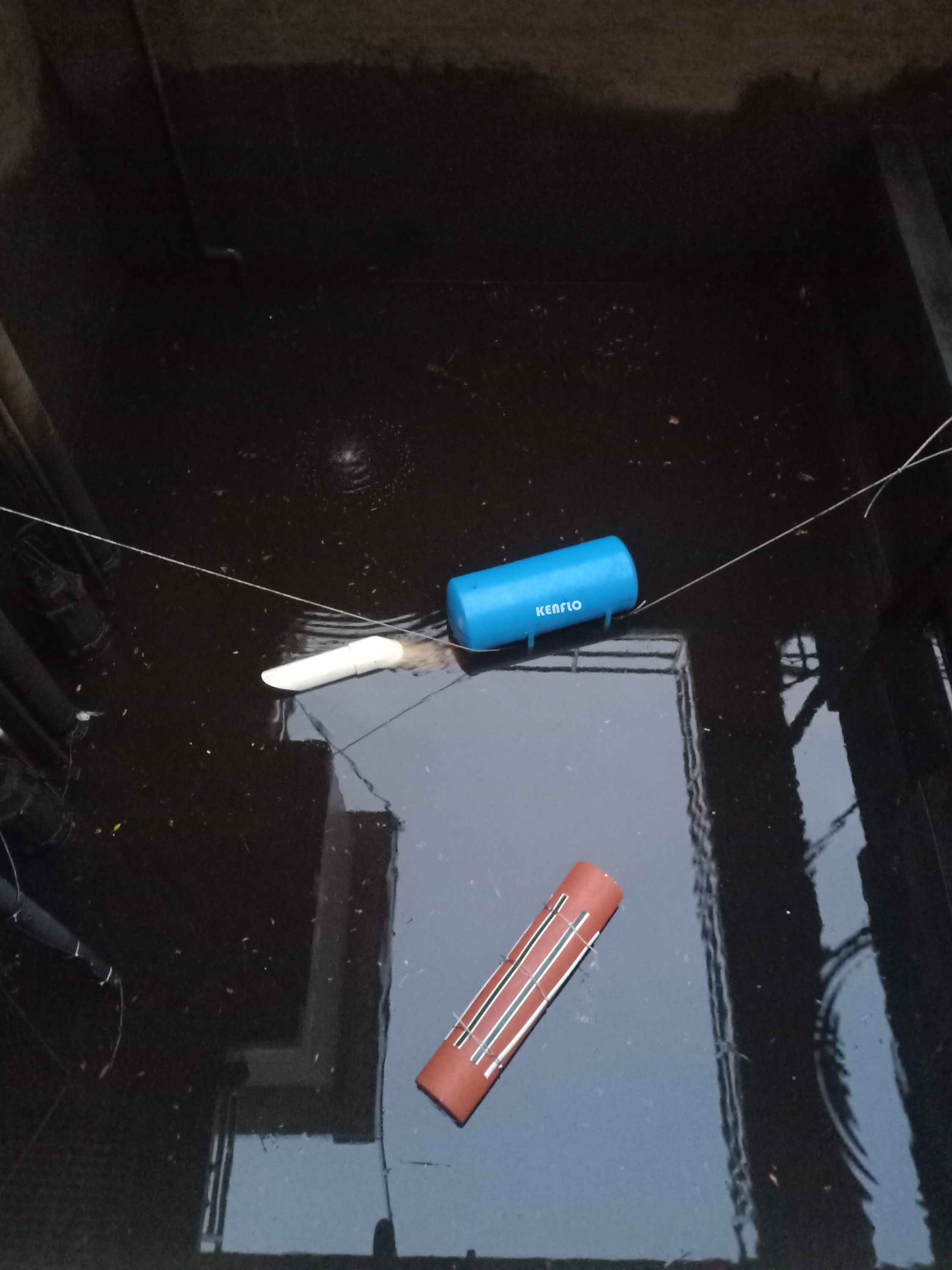

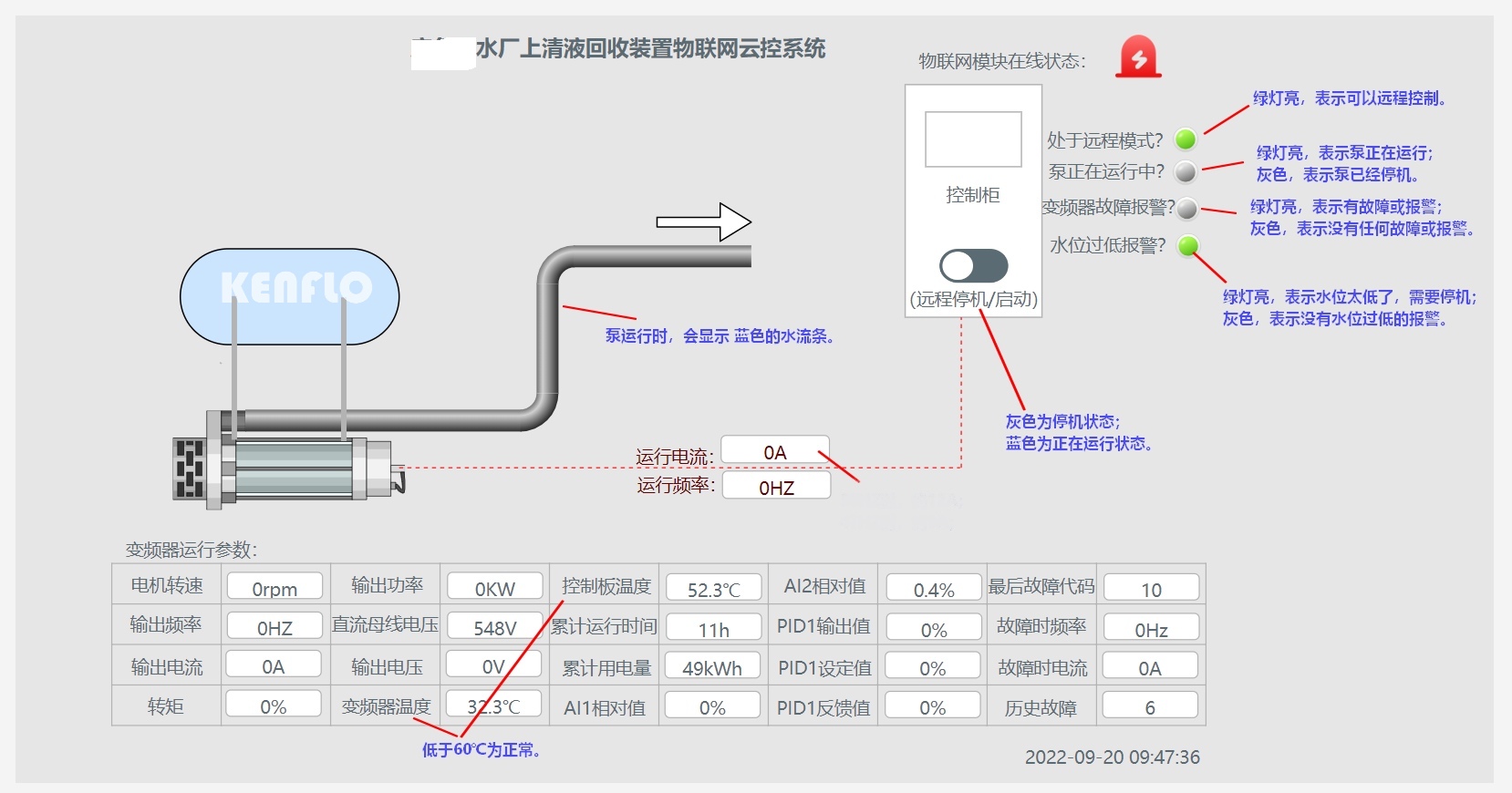

The traditional supernatant recovery usually uses a self priming pump or submersible pump with a fixed suction port. When there is a large amount of sludge deposition at the bottom of the pool and the sludge is high, part of the sludge will also be pumped in. The buoy type supernatant extraction device of KENFLO Pump Co., Ltd. floats on the water surface, and always pumps clear water about 200mm from the surface with the automatic rise and fall of the water level. At the same time, the buoy type supernatant extraction device is equipped with KENFLO's Internet of Things remote control system, which can use mobile phones and PC computers to remotely view the operation status and data in real time, and can conduct remote startup and shutdown operations.

The operation data that can be remotely monitored include:

Running speed;

Operating current;

Operating frequency;

Operating power;

Motor torque;

Accumulated power consumption;

Cumulative running time;

Fault status;

After the installation of the equipment, the equipment is officially put into operation after commissioning. The operation effect is good, the water on the surface is always drawn, and it can be remotely operated, and the machine can automatically stop, which is convenient for users.

Figure below: Float type supernatant water intake device after installation

Figure below: Configuration screen of IoT remote cloud control system

The video of remote monitoring screen is as follows:

If you need to know more about KENFLO's float type supernatant extraction device, please contact us at 0752-5571198.

共有 0 条评论